burst strength tester pharma|bursting strength tester procedure : wholesaling Bursting strength: Bursting strength is expressed as the maximum uniformly distributed pressure, applied at right angles to its surface, that a single sample piece can withstand under test conditions. The Burst index is the bursting strength divided by the grammage (ISO 2758-2001). Bursting strength compensated: The bursting strength value with . Receita de penne à ratatouille

{plog:ftitle_list}

WEB1 de dez. de 2023 · A BET7K é a plataforma que atualmente oferece maior bônus de 100% no depósito. O valor final pode chegar a R$7000. Bônus: 100% até o primeiro depósito máximo de R$7000; Necessário cumprir regras e termos de uso para retirada do valor; Registre-se Aqui; Leia também: Saiba como ganhar R$5 para jogar apenas .

SOP for operation, calibration, and maintenance of Bursting Strength Tester used to analyze the packing material of drug products. OBJECTIVE. To provide a procedure for the operation of Bursting Strength Tester. SCOPE. Applicable to the Bursting Strength Tester in Quality Control Department. . Note down the gauge reading in analytical test report as bursting strength which is indicated by the red pointer ( Maximum pressure at burst point ). Remove the tested sample by rotating the clamp wheel in anti-clock wise direction and then fix a new sample.Bursting strength: Bursting strength is expressed as the maximum uniformly distributed pressure, applied at right angles to its surface, that a single sample piece can withstand under test conditions. The Burst index is the bursting strength divided by the grammage (ISO 2758-2001). Bursting strength compensated: The bursting strength value with .

During burst testing, a package’s internal pressure is increased until it ruptures. This can be either a materials failure or seal failure. Because burst testing is a destructive test, the intact test sample cannot be recovered following the testing process. Burst testing is accomplished with the use of compressed air.The burst strength of Liveo™ Pharma Tubing was tested for all durometers . Burst strength test based on ASTM D380-94 Standard Test Methods for Rubber Hose (reapproved in 2012; American Society of Testing and Materials; W. Conshohocken, PA 19428-2959) and ISO 1402 Rubber and Plastic hoses and hose assemblies-Hydrostatic testing. .

characteristic of the package. There are two basic types of seal strength testing addressed in ISO-11607: tensile strength testing and burst or creep (inflation) testing. Tensile seal strength testing (ASTM F88) uses a defined width sample (25.4mm) of the package seal perimeter. A jaw moving at a defined constant rate 10 to 12 in/min. pullsThe HydroBurst Burst Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the burst strength and expansion of knitted fabric, woven fabric, non-woven fabric, laminated fabric, elastic woven fabric, paper, and other materials when subjected to stress in both warp and weft directions, as well as in all other directions, to get the material’s burst strength. Pharmaceutical & Medical Packaging News staff . ISO 11607 addresses two types of seal-strength testing: tensile strength testing and burst or creep testing. Pull it apart. Tensile seal-strength testing (ASTM F88) uses a defined width sample (25.4 mm or 1 in.) of the package seal perimeter. A jaw moving at a defined constant rate (10–12 in .A Bursting Strength Tester, also known as a Mullen Tester or a Burst Tester, is a precision instrument that is designed to measure the bursting strength of various materials. The BS testers are primarily used in the packing industry so that they can assess the ability of the material to withstand pressure.

AS/NZS 1301-403s:1997, Methods of test for pulp and paper — Bursting strength of paper. Appita standard 1 [5] TAPPI T 1200, Interlaboratory evaluation of test methods to determine TAPPI repeatability and reproducibility [6] Brauns O., Danielsson E., Jordansson L., Svensk Paperstidning 23 867 (1954) 1) [7]

sop for bursting strength tester

The 6D(SG) Soft Gelatin Capsule Tester is the soft gel variant of the world renowned model 6D tablet hardness tester. It is capable of measuring any shape liquid and cream filled Soft Gelatin Capsules for deflection and burst strength.Burst testing, also known as burst strength testing or burst pressure testing, is a crucial evaluation technique used across industries to determine how much internal pressure a material can withstand before it ruptures or bursts. This test sheds light on the structural integrity and reliability of materials, ensuring they can withstand the .Customised engineering example Plastic sachets with welded seams are frequently used for measured applications of liquids, creams and gels. A quick quality test for their integrity involves compression either to burst, or to resist a defined compressive force. This may require containment for spillage, but also for alignment. Our client was testing pharmaceutical sachets. SKYE 2000a is a microprocessor-controlled package test system that gives an accurate and totally reproducible measurement of package integrity and seal strength. Analyze your packages for immediate and potential problems.

Both measure the bursting pressure and distension height of multiple samples and then calculate an average bursting strength after subtracting the pressure to expand the bare diaphragm. The Autoburst is a heavy duty hydraulic system while the PnuBurst is pneumatic and offers additional testing capabilities. Bursting Strength Testers

PHARMA DEVILS QUALITY CONTROL DEPARTMENT 1.0 OBJECTIVE: To lay down a procedure for Operation and Calibration of Bursting strength tester. 2.0 SCOPE: This SOP is applicable for Operation and calibration of Bursting strength tester in the Quality Control Department. 3.0 RESPONSIBILITY: Officer, Executive – Quality Control Department

Introducing the upgraded version of our QualiBurst-MP Automatic Mullen-type Digital Burst Strength Tester, designed to measure the bursting strength of paper, corrugated paper, cardboard, fabrics, leather, and more. .

bursting strength tester procedure

bursting strength tester manual

burst tester calibration

Bursting strength of test specimen is expressed in terms of Kg/cm². The bursting factor can be calculated by the following formula . Bursting factor = bursting strength / Grammage . Working Principle of Bursting Strength . This procedure is applicable for Bursting strength tester, Installed in quality control laboratory . 3.0 RESPONSIBILITY 3.1 Doing: Technical Assistant/Executive 3.2 Checking: Executive/Manager 4.0 ACCOUNTABILITY Head of the Department 5.0 PROCEDURE 5.1 After completion of the testing, remove the sample from the instrument. 5.2 Switch off the mains.

A Bursting Strength Tester is a specialized instrument used to determine the bursting strength of various materials. This strength is defined as the pressure required to rupture the material when .

The testing method for heat seal strength is as follows: choose suitable heat seal parameters according to the specific testing standards; heat seal a piece of PVC sheet or a piece of PVC/PVDC laminated sheet (to stack the adhesive side of the aluminum layer with the PVC sheet) at the size of 100mm×100mm with a heat sealer; then, cut the .

Bursting strength is the force required to burst or rupture the material under testing. Bursting strength of test specimen is expressed in terms of Kg/cm². It is measured by giving hydraulic pressure through a rubber diaphragm on the test specimen. www.prestogroup.com Top View Side View Front View 600 mm 600 mm 450 mm 540 mmThe digital burst strength tester enables precise burst strength measurement, ensuring reliable results. Pharmaceuticals: Validates the integrity of foil used in blister packs and other packaging, ensuring drug safety by adhering to ISO 2759 burst resistance testing standards.The Pouch Burst Tester is used to test the maximum internal pressure a pouch can withstand without the seals or the body rupturing. This test can be considered as a full seal integrity / seal strength test of a formed pouch. The weakest portion of the pouch can be quickly and easily detected. And you can differentiate between a Weak Seal pouch and a Weak Laminate pouch.

Chemical Analysis in Corrugated Box Testing #1– Bursting Strength Test. WHAT: Test box strength when subjected to pressure; WHY: To determine exact weight a box can carry, rough handling; The Mullen Test or Bursting Strength Test checks the toughness of the walls of the corrugated board when subjected to force or pressure.Bursting Strength Tester is a reliable index of measurement of strength and performance of materials like paper, paper boards, corrugated boards and boxes, solid fiber boards, filter cloth, industrial fabric, leather and Rexene. With the help of a bursting strength tester, industries can ensure the best quality of products to their clients. .We determine bursting strength using a digital hydraulic paper or digital hydraulic board burst tester as shown below. Burst index (kPa.m2/g) = burst strength/basis weight. Standards and accreditation. Smithers UKAS ISO 17025 accredited testing can be performed to both British and International standards; BS 3137, BS 2922:1, ISO 2758 and ISO 2759.

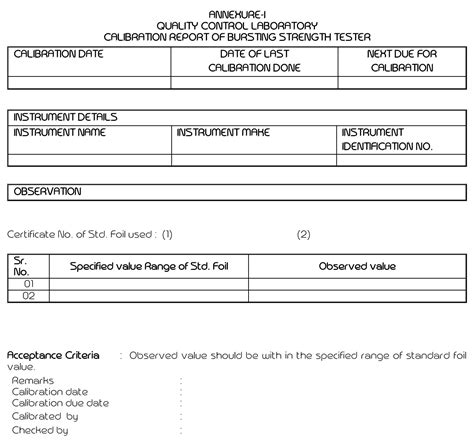

Bursting strength test apparatus is calibrated by authorized external agency for pressure gauges. 7.2.2 Calibration of bursting strength capacity: 7.2.2.1 Use certified standard Aluminum Foil of 5.6 Kg/cm² and 15.0 Kg/cm² for calibrating of bursting strength capacity. 7.2.2.2 Record the calibration details as per Annexure-II.

very hard vocabulary test

very hard vt motorcycle permit practise tests

WEB1 de fevereiro de 2024 Por Vagner Neubert. Tabela de Conteúdos. Melhores Notebooks que Rodam The Sims 4 de 2023. 1º – Dell Alienware M15 R7 M20P. 2º – Acer Gamer .

burst strength tester pharma|bursting strength tester procedure